Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

What machines are needed for candy production plant

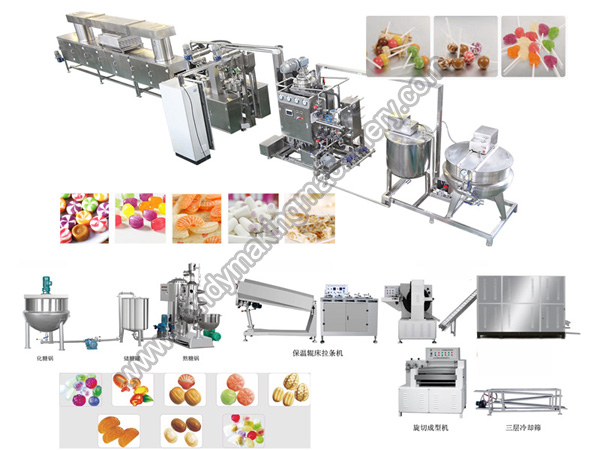

You need to choose different equipment according to your own positioning. If you want to make gummies, you usually choose a casting production line. If you want to make hard candies or lollipops, you usually choose a stamping production line or a casting production line. Large scale candy production requires high-end and efficient candy making machine and molding machines with high automation. For example, if you want to make candy casting production lines, they have automatic addition of nuts and support for continuous production

The characteristics of continuous casting production operation can meet the large-scale and high-efficiency production needs of large enterprises. Sugar boiling machine: used to boil sugar and other ingredients into syrup, it is a key equipment for making candy. The sugar boiling machine can precisely control the temperature and time to ensure the quality of the syrup.

Molding machine: Pour the boiled syrup into the molding machine and make various shapes and sizes of hard candies according to different molds. The accuracy of the molding machine directly affects the appearance and quality of the candy.

Stamping machine: used for making hard candy, forming sugar strips after stamping and cooling through molds, suitable for traditional hard candy production.

Casting molding machine: By pouring sugar solution through a mold and cooling it to form, it is suitable for soft candies and injection candies (such as QQ candy), and supports diversified shape customization.

Candy crisp fruit machine: It uses flour as raw material to make Zongzi shaped puffed candy through molds, which has multiple functions.

Cooling equipment: After the hard candy is made, it needs to be cooled and shaped. Cooling equipment can quickly and evenly cool candies by controlling temperature and wind speed, thereby improving production efficiency and ensuring product quality.

Classification and functions of core equipment

Packaging and packaging equipment

Counting and packaging machine: Automated counting and packaging of tablet candies (such as compressed candies, effervescent tablets), common models support 1-10 pieces for packaging.

Sealing machine: used for sealing bagged candies, including portable mini sealing machine and fully automatic three edge sealing equipment, suitable for different production needs.

material handling equipment

Puffing machine: Processing raw materials such as corn and flour, it can produce puffed candies or sugar sticks, and supports diversified raw material processing.

Coating machine: used for chocolate or sugar coating wrapping (such as fruit chocolate), with automatic temperature control function.

auxiliary equipment

Crusher: Processing expired candies or separating raw materials to improve raw material utilization.

Filling machine: suitable for semi-automatic filling of paste candies (such as peanut butter filled chocolate).

Equipment selection suggestions

Small production line: Prioritize multifunctional equipment such as mini sealing machines and single stamping machines to reduce costs and flexibly adapt to small batch production.

Automation requirements: Fully automatic counting packaging machines and 8-channel electronic bottling machines can significantly improve efficiency and are suitable for medium and large factories.

Special process: The injection molded candy requires a double-layer injection needle pouring equipment, while the infiltration machine and freeze-drying equipment are used for innovative categories (such as freeze-dried fruit candy).

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemapManufacturer Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line chocolate production line chewing gum production line Popping boba production line