Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

The main processing techniques for toffee are as follows

Traditional boiling method

Process flow of toffee processing machine:

1. Raw material preparation: Prepare light cream, sugar (white sugar, brown sugar, etc.), maltose, butter, salt and other raw materials.

2. Mixed heating: Mix light cream, sugar, maltose, etc. and heat until the sugar is completely dissolved to form a syrup.

3. Boil syrup: Continue heating the syrup and stirring continuously to prevent sticking to the pot. As the water evaporates, the syrup gradually thickens and the color darkens.

4. Temperature control: Use a thermometer to monitor the temperature of the syrup, usually boiled to between 150 ℃ -160 ℃.

5. Add auxiliary materials: After the syrup reaches the desired temperature, add nuts, chocolate chips and other auxiliary materials, stir quickly and evenly.

6. Molding cooling: Pour the mixed syrup into a mold or non stick baking tray, flatten it, and cool it to room temperature.

7. Cutting packaging: After toffee is completely cooled and hardened, cut it into small pieces for packaging.

Features of toffee processing machine: Traditional method, rich taste, and pure flavor.

-Need to master the fire and temperature, with high operational requirements.

Continuous production line processing technology process:

1. Raw material mixing: Using large-scale mixing equipment, the raw materials are automatically mixed in proportion.

2. Continuous boiling: Using a continuous sugar boiling equipment, the syrup is heated and boiled in a pipeline, with precise temperature and time control.

3. Online addition of auxiliary materials: Automatically add nuts, chocolate and other auxiliary materials on the production line, mix evenly.

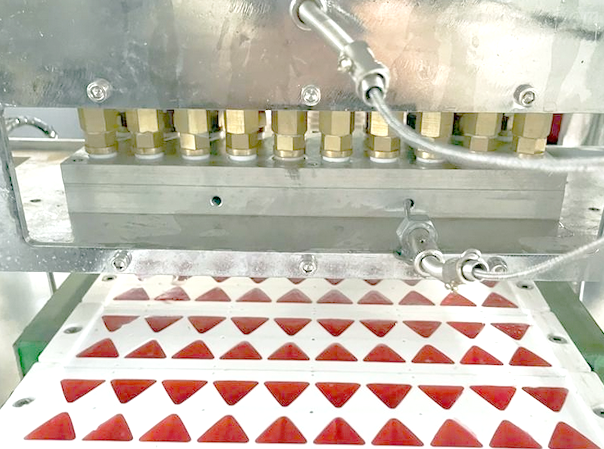

4. Molding cooling: The syrup is molded into a specific shape through a molding machine and rapidly cooled through a cooling tunnel.

5. Cutting and packaging: automatic equipment completes cutting and packaging to improve production efficiency.

characteristic:

Suitable for large-scale production, high efficiency, and good product consistency.

Professional equipment and production lines are required, with a significant investment.

Low temperature slow cooking process:

1. Raw material preparation: Same as traditional methods.

2. Low temperature slow cooking: Use low-temperature slow cooking equipment to heat the raw materials at a lower temperature for a long time, such as boiling at 80 ℃ -90 ℃ for several hours.

3. Stirring and mixing: Continuously stir to ensure that the syrup is evenly and thick.

4. Subsequent steps: the same as the traditional method, adding auxiliary materials, forming cooling, cutting and packaging.

characteristic:

Low temperature processing can better preserve the flavor and nutrition of raw materials.

The processing time is relatively long and the equipment requirements are high.

Process flow of vacuum boiling method:

1. Raw material preparation: Same as traditional methods.

2. Vacuum boiling: Heat the syrup under vacuum conditions to lower its boiling point and accelerate water evaporation.

3. Temperature control: Due to the decrease in boiling point, syrup can reach the desired concentration at lower temperatures.

4. Subsequent steps: the same as the traditional method, adding auxiliary materials, forming cooling, cutting and packaging.

characteristic:

Vacuum boiling can prevent syrup from coking and achieve a more uniform color.

-The equipment cost is high and the operational technical requirements are high.

Summary: There are various processing techniques for toffee, and suitable methods can be selected based on production scale, product requirements, and equipment conditions. Traditional methods are suitable for small-scale handmade production, continuous production lines are suitable for large-scale industrial production, and low-temperature slow cooking and vacuum boiling can improve product quality and taste.

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemapManufacturer Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line chocolate production line chewing gum production line Popping boba production line